Scale Meets Precision

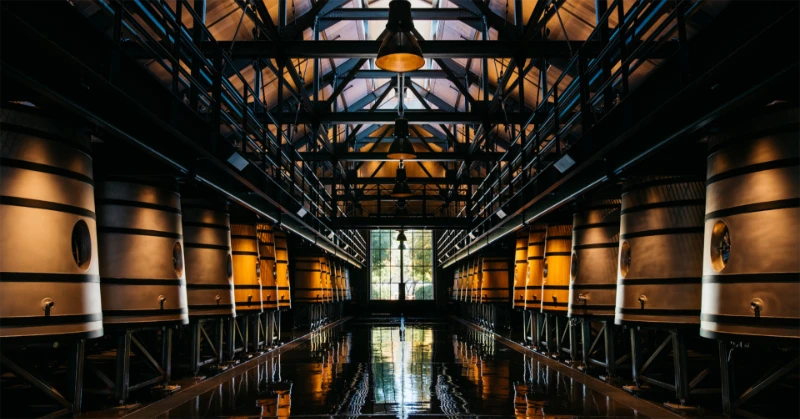

Rodney Strong Vineyards is a premium winery in Sonoma County committed to sustainable farming and crafting world-class wines. To meet growing demand, they undertook a massive renovation to modernize their cellar and increase production capacity for their Cabernet, Pinot Noir, and Bordeaux blends.

The Challenge

The winery faced a critical dilemma: how to significantly increase capacity within an existing footprint without sacrificing the hands-on quality control required for premium winemaking.

- Space vs. Volume:

They needed to fit more fermentation power into a limited space (increasing from ~40 round tanks to 57 square tanks). - Operational Complexity:

Managing 57 individual fermentations simultaneously would be impossible to do manually without a massive increase in labor. - Precision Requirement:

Winemaker Justin Seidenfeld needed a way to monitor the delicate temperature curves and fermentation health of every single tank in real-time, 24/7, without living in the cellar.

The Solution

TankNET® by Acrolon Technologies, Inc.

While the physical expansion utilized custom La Garde square tanks, the "brainstem" of the new cellar is TankNET®. Rodney Strong implemented TankNET®'s web-based fermentation management system to bring intelligent automation to their new high-density cellar.

Key Benefits

- Total Mobility & Control:

The winemaker is no longer tethered to a control room. Using the TankNET® mobile app, Justin Seidenfeld can monitor real-time data and make critical adjustments to temperatures from his smartphone, whether he is in the vineyard, at home, or traveling. - Automated Pump-Overs & Punch-Downs

TankNET® automates the labor-intensive processes of pump-overs and punch-downs. With a simple "swipe" on a screen, the system can trigger these actions, ensuring consistent cap management and extraction without requiring cellar hands to manually operate valves for every cycle. - Precision at Scale:

Managing 57 tanks in a tight space creates a complex thermal environment. TankNET® creates a feedback loop that monitors fermentation curves instantly. Custom alarms alert the team immediately if a tank deviates from its target, allowing for "proactive winemaking" rather than reactive fixing. - Seamless Integration:

TankNET® was designed to integrate perfectly with the customized La Garde tanks. It manages the glycol cooling jackets (which were increased from 3 to 6 per tank for better thermal control) and the heating systems, ensuring the "dance" of fermentation happens exactly as the winemaker intends.

Results

Increased capacity by 240 tons per vintage without expanding the cellar's footprint.

Ensured precise quality control across all 57 tanks, maintaining standards despite higher volume.

Reduced manual labor, enabling staff to focus on wine quality and strategy instead of repetitive tasks.

A Future-Proof Partnership

Rodney Strong's reliance on TankNET® extends well beyond this renovation; since 2004, the winery has successfully operated the platform across three distinct generations of hardware. The system's architecture allows the original Free Topology (FT) units, the renovation's Power Line (PL) controllers, and the latest Mesh TC-1s to work seamlessly together on a single network.

Starting in 2025, the winery began a phased upgrade to replace their 22-year-old operational FT units with next-generation Mesh technology over two harvests. This backward compatibility ensures that Rodney Strong can modernize at their own pace, benefiting from the latest wireless advancements without disrupting their established workflow..

Conclusion

For Rodney Strong Vineyards, TankNET® turned a high-volume cellar into a precision instrument. It empowers the winemaking team to maintain their "small lot" attention to detail even at a much larger scale, proving that technology can be the key to preserving artisanal quality in a growing winery.