Fermentation Controller

Automates pump-overs and aeration while keeping temperature stable - less labor, better consistency.

Key Applications:

- Automated pump-overs for red wine

- Stable fermentation temperatures

- Simple retrofit with Wi-Fi/Mesh

- Works with Real-time Brix

Key Features

Precise Heating and Cooling

Jump starts fermentation with gentle heat, then seamlessly transitions to free-rise

Pump-Over Control

Automated pump-overs for consistent extraction and flavor development and labor savings

Venturi Control

Automate aeration to support yeast health and wine structure

Real-Time Brix Integration

Works with Acrolon's brix monitoring solution for actionable, real-time fermentation insights

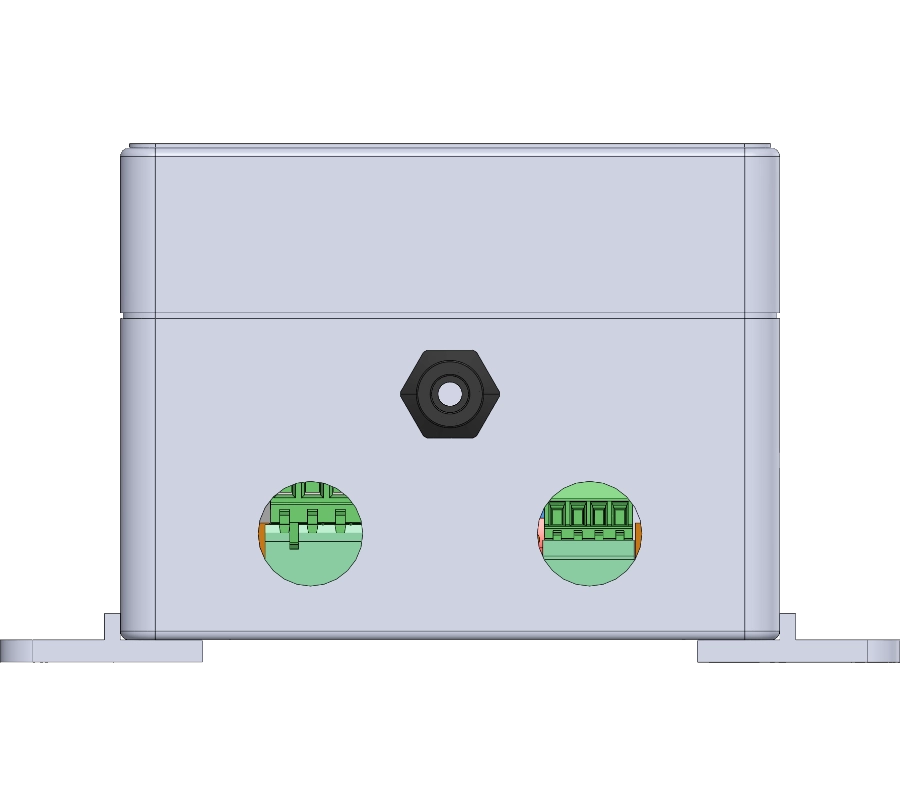

IP-67 Rated Enclosure

Fully sealed, water-tight, and dust proof enclosure for harsh cellar and outdoor environments

Wi-Fi 6 or Mesh Networking

Robust and cost effective wireless integration with TankNET® software

Overview

The TC-1 builds on the trusted temperature control and wireless connectivity of the PL-1, adding intelligent automation features specifically designed for red wine fermentations.

In addition to precise heating, cooling, and auto mode, the TC-1 includes dedicated outputs for automated pump-overs and venturi control, bringing hands-free efficiency to cap management and oxygenation during peak fermentation activity.

With support for WiFi 6 or Thread Mesh networking, the TC-1 connects effortlessly to TankNET® fermentation software for remote control, scheduling, and real-time fermentation insights.

Built for winemakers who expect more from their controls, the TC-1 delivers simple, reliable, and scalable automation for red wine fermentation.

Why Choose it

- Built for red wine

- Reduces manual work

- Pump-over & Venturi controls

- Scales easily as your cellar grows

Product Datasheet

Download DatasheetSpecifications

Model

TC-1

Operating Temp.

0°C to 50°C

Safety Rating

ETL Listed

Input Voltage

120VAC 50/60Hz at 0.15A

24VAC 50/60Hz at 0.39A

Enclosure

Polycarbonate, UL50, NEMA-4X Rated

Dimensions (with brackets)

164mm x 120mm x 94mm

6.5" x 4.7" x 3.7"

Relay Output

- Cool Relay: Form-C, Fused @ 2A at 120VAC

- Heat Relay: Form-C, Fused @ 2A at 120VAC

- Pump: Form-A, Fused @ 2A at 120VAC

- Venturi: Form-A, Fused @ 2A at 120VAC

Probes

- Input 1: Two-wire temperature probe

- Input 2: Temperature Probe / 4-20mA Sensor

* Specifications subject to change without notice