Engineered for the Crush

TankNET® is built to meet the rigorous demands of harvest - delivering total reliability and control when it matters most.

and pulse cooling.

at every scale

Total Fermentation Control

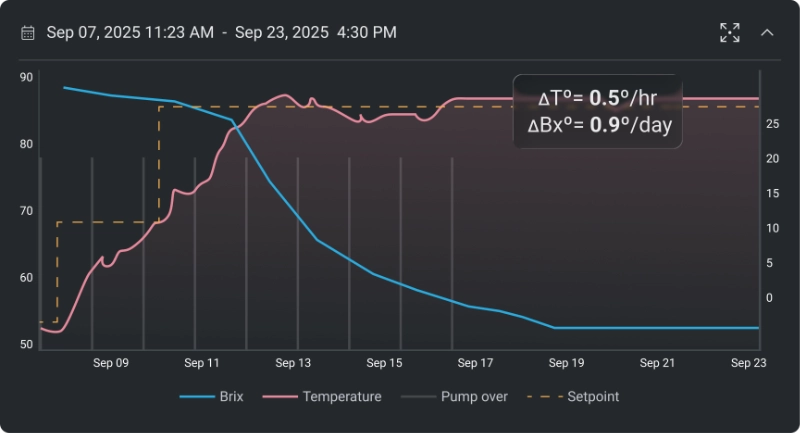

Real-Time Fermentation Insight

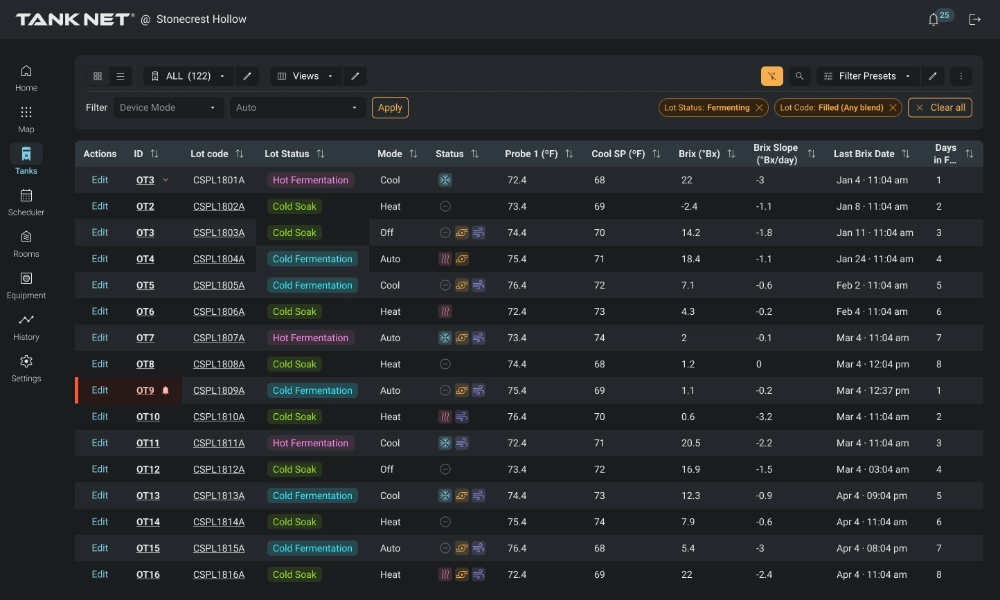

Cellar Activity at a Glance

Streamlined Tank Management

Product Lineup

Standalone controls ready to network when you are - for any need and any budget.

TC-1 Controller

Enhanced automation. Precision control for temperature, pump-overs, and aeration.

View TC-1

PM Series

Advanced fermentation control. Temperature, pump-overs, real-time Brix, and Redox.

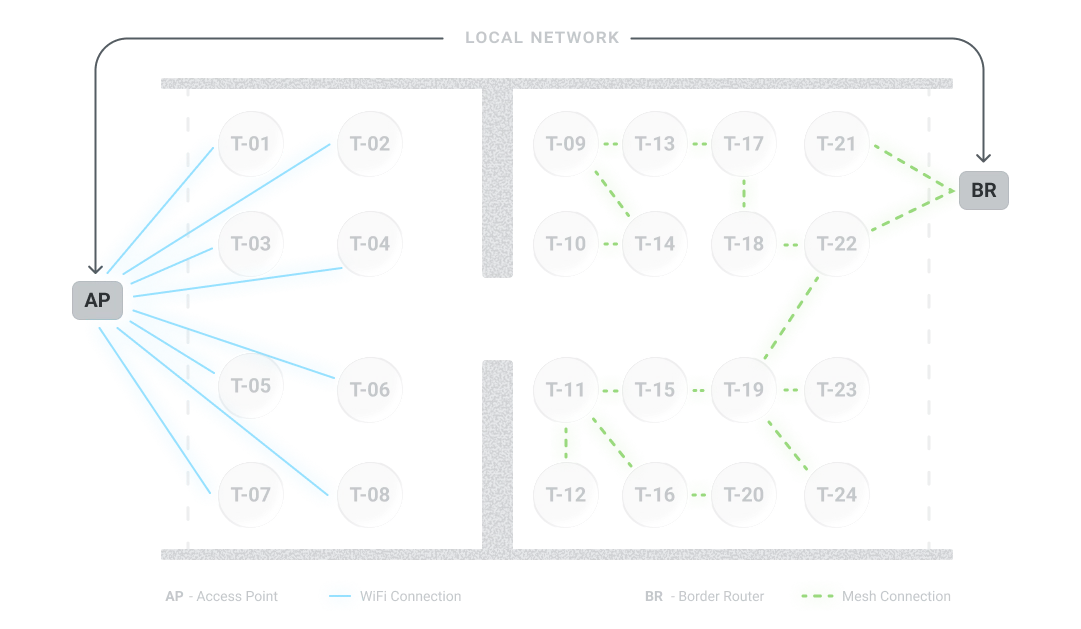

View PM SeriesEasy, Scalable Networking

Facility Intelligence

TankNET® extends beyond tank control to manage energy use and cellar conditions — helping reduce operating costs while maintaining safe, stable production environments.

Energy-Aware Cooling

Flatten energy spikes during Crush. TankNET® uses pulse cooling and demand-based control to manage chiller load, reducing peak demand and energy costs while keeping fermentation curves tight.

Integrated Cellar Safety

Manage temperature, CO2 buildup, humidity, and night-air cooling from the same dashboard that runs your fermentations - protecting your wine while reducing energy use.

Built For Wineries

Industrial-grade Wireless Controllers

IP67 wash-down-rated hardware designed to withstand moisture and temperature swings.

Web-based Software

Run TankNET® in the cloud or on-premises, with the same full-fidelity experience on any device.

Works with Existing Equipment

Compatible with industry-standard tank valves, VFDs, and power standards.

Cellar <-> Office

A single source of truth - built for today, ready for what's next.

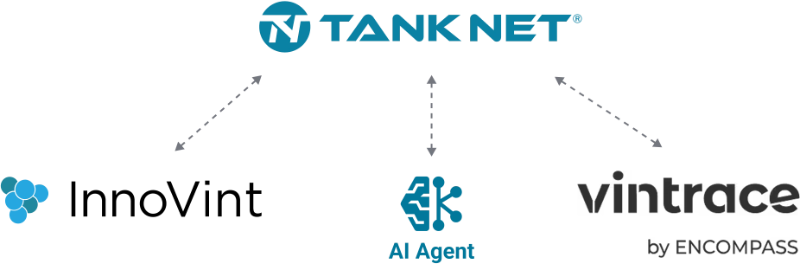

TankNET® connects real-time cellar activity with your production management system, eliminating double entry and creating a single source of truth from fermentation through compliance.

-

Seamless Sync: We offer native integrations with leading winery management platforms like InnoVint and Vintrace

-

Audit-ready Lot Histories: Maintain complete, time-stamped records that support traceability and accurate TTB reporting.

-

Structured Data for Predictive AI: Capture clean, consistent production data that prepares your winery for advanced analytics and future AI-driven optimization