Protect Your Craft

Fermentation doesn't stop at 5PM, and neither does TankNET®. Don't let a chiller trip or a stuck valve ruin your weekend. TankNET® monitors your cellar 24/7 and sends intelligent alarms so you can react before quality is compromised.

and pulse cooling.

at every scale

Peace of Mind is Built-In

Step away from the cellar without losing touch. TankNET® keeps you in control from anywhere - whether you are on the brew deck, in the office, or at home.

Consistency You Can Taste

Make your flagship beer taste the same in July as it does in December. TankNET® automates precise temperature curves and eliminates overshoot, protecting yeast health and flavor integrity.

Data-Driven Brewing

Retire the clipboard. TankNET® captures real-time fermentation data to provide the actionable info you need to spot lag phases and prevent stalls before they happen.

Product Lineup

Standalone controls ready to network when you are - for any need and any budget.

PM Series

Advanced fermentation control. Monitor Temperature, Specific Gravity, and pH.

View PM SeriesEasy, Scalable Networking

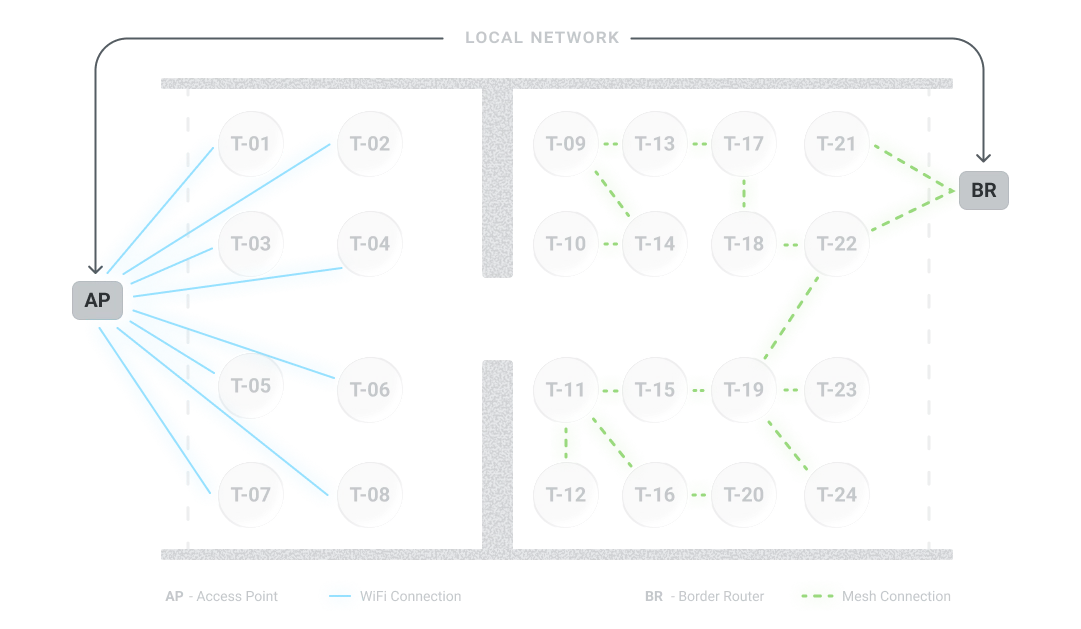

Brewery <> Office

Create a single source of truth and streamline your brewery operations.

Seamless Sync

TankNET® pushes temperature and gravity data directly into The 5th Ingredient and Breww. Stop data silos before they start and ensure your digital batch records always match reality.

- Single Source of Truth

- Streamlined Quality Audits

- Open API Connectivity

Built For Breweries

Industrial-grade Wireless Controllers

IP67 wash-down-rated hardware designed to withstand moisture and temperature swings.

Web-based Software

Run TankNET® in the cloud or on-premises, with the same full-fidelity experience on any device.

Works with Existing Equipment

Compatible with industry-standard tank valves, VFDs, and power standards.