Built for the Modern Cellar

Hosted in the cloud or on-premises

TankNET® is a powerful, affordable control platform that simplifies fermentation management at any scale. By automating precise cellar workflows, we help you reduce labor and slash energy waste while perfecting your craft.

and pulse cooling.

at every scale

Unified Control

TankNET® manages your entire production environment. Our software integrates real-time fermentation data with plant equipment and compliance tools, providing a single source of truth for your cellar team.

Key Capabilities:

- Precision Fermentation Control

- Operational Efficiency

- Cellar Command

Precision Fermentation Control

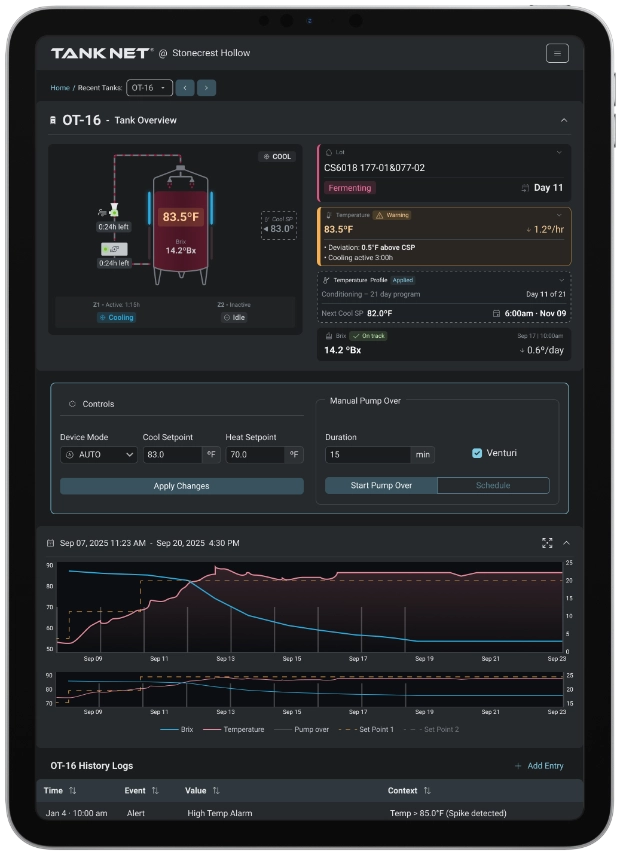

Precise Temperature Control

Maintain ideal fermentation conditions with accurate, reliable, and energy-efficient temperature control that adjusts automatically to each stage of fermentation.

Real-time Density Monitoring

Monitor °Brix or SG in real time, detect deviations from expected kinetics, and activate alerts or automation to prevent fermentation stalls.

Automated Pump-Overs

& Aeration

Enhance extraction, support healthy ferments, and cut labor with scheduled cap management and aeration.

Full fermentation timeline

Visualize each fermentation with rich, interactive timelines of temperature, °Brix, pump-overs, and key events - making it easy to spot trends, compare lots, and act with more confidence.

Cellar Command

Activity at-a-Glance

Visualize your entire cellar with interactive maps showing real-time tank temperatures, status, control activity and alerts.

Tank Management

Manage large operations easily with custom tank groups, and dynamic filters that keep you focused on what's important.

Cellar & Barrel Rooms

Control temperature, humidity, and CO₂ with precision to protect your product and your people.

Real-time Data Capture

Capture Brix measurements, control changes, and tasting notes as they occur into a single auditable timeline

Operational Efficiency

-

OT24:High temperature +2.3ºF/hr

-

OT25:Approaching temp. threshold 1.4ºF/hr

Smart Alerts & Notifications

Stay focused with flexible alerts that surface only what matters. Prioritize, aggregate, and throttle notifications to eliminate noise and ensure critical issues get noticed.

Compliance Integration

Sync real-time fermentation data with Vintrace, Breww and others. Eliminate double entry, and keep production teams tightly aligned.

Energy Saving Control

Reduce utility costs and extend your equipment's operational life using smart control strategies, including pulse cooling, dynamic chiller control, and night air ventilation.

Secure Access

& Audit Logs

Track every change with a detailed audit log and assign user roles to control access, ensuring accountability, traceability, and operational security across your team.