PM-Series

Custom Control Panel Solutions for Fermentation and Environmental Control

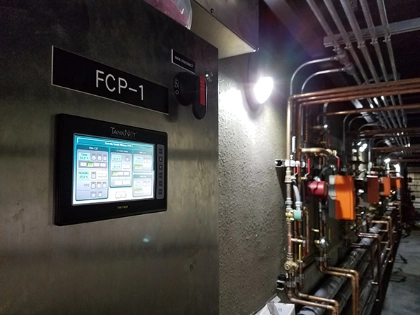

The TankNET® PM-Series represents the core of our customized control solutions. Whether you need to manage a single fermentation tank, a complex cellar environment, or a 100-tank facility, we design and build UL-rated control panels centered around the interface that fits your operational needs.

Complete Turnkey Panel Solutions

We don't just sell you a controller; we deliver a complete, turnkey panel solution. Every PM-Series unit is engineered to your specifications and arrives ready for installation.

Key Applications:

- Hardware: Internal power supplies, required I/O, and labeled terminals

- Documentation: Comprehensive schematics and wiring diagrams

- Ready for Installation: Engineered to your exact specifications

- Integration: Seamless, out-of-the-box TankNET® connectivity

Applications

Advanced Fermentation

Comprehensive control including multi-point temp sensing, pulse-cooling, pump-over automation (variable spray/venturi), and real-time kinetics monitoring (Brix & REDOX).

Cellar Environments

All-in-one coordination of mechanical heating/cooling, humidity, CO2 safety exhaust, and night-air cooling..

Smart Equipment Control

Intelligent management of chillers and heaters, featuring smart compressor staging and demand-aware load balancing.

Custom Logic

The PM-Series is an industrial PLC-style platform capable of handling virtually any custom I/O requirement you can throw at it.

Seamless Software Integration

Because every panel is pre-configured for TankNET® Professional Software, you get immediate access to the full power of the ecosystem. Whether you have one PM-5 or a network of PM-10s, you gain unified access for remote management, data trending, and critical alerts via any web browser or mobile device.

Model Comparison At-A-Glance

| Feature | PM-5 | PM-7 / PM-10 |

|---|---|---|

| Display Size | 5-Inch Touch Screen | 7-Inch or 10-Inch Touch Screen |

| Primary Use | Environmental Control |

Advanced Fermentation Management Multi-Tank / High-Density Central Control |

| Capacity | Individual Tank or Room | Up to 100+ Tanks/Zones |

| Connectivity | Single Ethernet (Wi-Fi Optional) | Dual Ethernet (Wi-Fi Optional) |

| I/O Architecture | Built-in Local I/O | Unlimited Expansion (Din-rail and remote I/O) |

| Panel Type | Compact Panel Mount | Centralized Master Panel |

Frequently Asked Questions

While our standard thermostats are the industry benchmark for individual tank control, the PM-Series is the preferred solution in three specific scenarios:

- Retrofitting: If you are replacing an older centralized system, the PM-Series (Centralized Architecture) allows you to reuse your existing conduit and wiring infrastructure, significantly reducing installation costs.

- Aesthetics: For "show cellars" where visual minimalism is a priority, the PM-Series allows controls to be centralized or hidden in remote sub-panels, keeping the tank faces clean.

- Customization: If your process requires complex logic - such as variable speed pump-overs, advanced environmental coordination, or custom I/O configurations-the PM-Series offers the robust, PLC-style capability required to handle it.

Yes. The TankNET® ecosystem is fully unified. You can easily mix PM-Series panels with our standard controllers (such as the PL-1, BT-1, or TC-1) in the same facility. You might use a centralized PM-10 for the main fermentation hall while using individual thermostats in the barrel room-all managed seamlessly from the same software interface.

Let's discuss your project.

Every facility is unique. Contact us to discuss your wiring infrastructure and control needs, and we will recommend the PM-Series solution that balances cost, aesthetics, and functionality.